1. The Role of 10k NTC Thermistors in Modern Temperature Sensing

In 2025, 10k NTC thermistors are still a top choice for designers. They offer great sensitivity, cost-effectiveness, and compatibility with electronic systems.The “10k” refers to the nominal resistance at 25 °C—i.e. R25 = 10,000 Ω. This base point allows standardization across many applications.

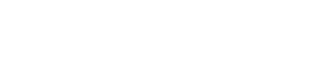

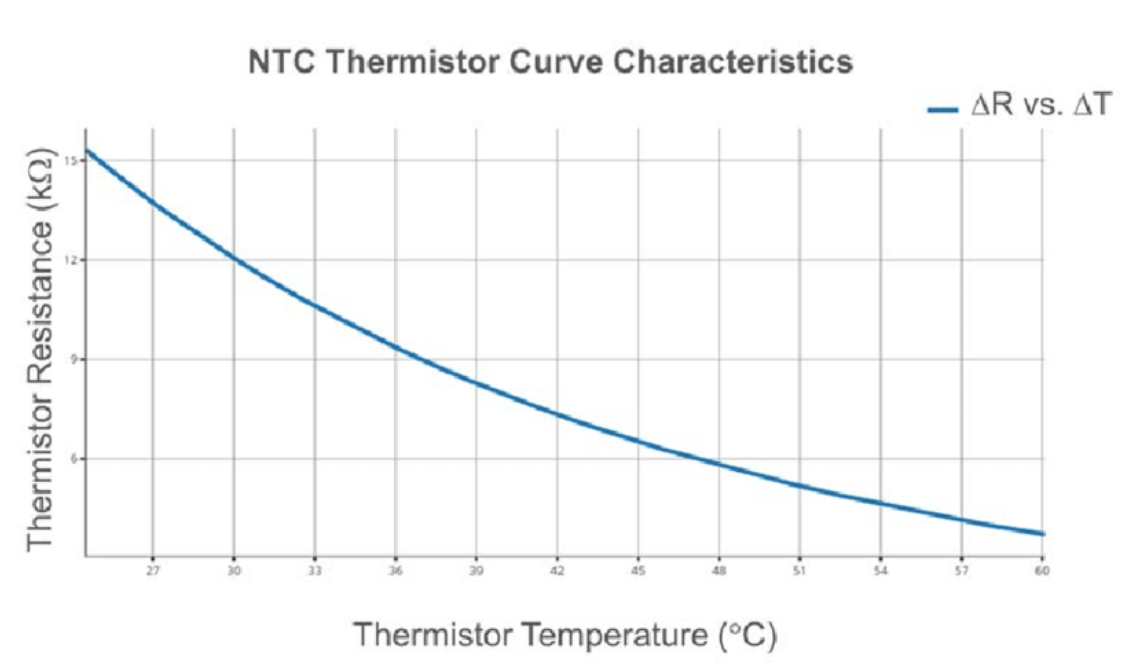

NTC thermistors are negative temperature coefficient resistors: as temperature increases, resistance decreases.This behavior is sharper than metals or silicon resistors. It makes them very sensitive in many thermal monitoring tasks.

2. R-T Behavior & Modeling with Public Data

A widely used reference is the Labfacility 10k NTC table (B25/85 = 3977 K), which maps temperature to resistance across –40 °C to +125 °C.

| Temperature (°C) | Resistance (kΩ) |

|---|---|

| –40 | 336.479 |

| 0 | 32.65 (approx) |

| 25 | 10.00 |

| 50 | 3.747 |

| 90 | 0.916 |

This nonlinear response is typically modeled via the B-parameter or the Steinhart–Hart equation. For instance, Electronics Tutorials uses B = 3455 for a 10k NTC spanning 25 °C to 100 °C. ([electronics-tutorials.ws]

3. Critical Parameter Considerations

3.1 Tolerance & Beta Stability

Common tolerances include ±1 %, ±2 %, ±5 %. For example, Amwei’s 10k device lists R25 ±1 % with Beta B25/85 = 3435 K ±1 %. [amwei.com] Stability of the Beta parameter over time and environmental cycling is crucial for long-term accuracy.

3.2 Thermal Time Constant & Self-Heating

The thermal time constant for many 10k NTC units is around 10–15 seconds. For instance, Handson’s 10k-3950 spec sheet lists 15 s.Meanwhile, self-heating (due to the measuring current) can artificially raise the sensor’s temperature and distort readings. Designers must restrict excitation current to limit the error to acceptable levels.

3.3 Operating Range, Packaging, & Drift

Many 10k NTC devices are rated between –40 °C and +125 °C. For example, Amwei’s product supports that same range. Packaging choices like epoxy coating or glass encapsulation affect drift. Hermetic and glass types usually offer better stability. Also, soldering must be carefully controlled: TME’s spec says soldering tip 6 mm away, ≤350 °C, ≤ 3 s.

4. Proposed Chart Visuals (Placeholders)

CHART: Resistance vs Temperature (R-T curve) — Plot using Labfacility / Vector Controls 10k NTC table

CHART: Self-Heating Error vs Excitation Current — show how error increases with higher current

5. Application Domains & Showcases

EV Battery & Thermal Management

Battery packs in electric vehicles generate internal heat. A stable 10k NTC thermistor is ideal for embedding into modules or battery cells. Focusensing’s thermistors offer good drift control and ruggedness, helping BMS maintain safe limits.

HVAC & Smart Thermostats

Many wall-mounted thermostat sensors use 10k NTC elements—e.g. Honeywell’s TB-WALL uses a 10k NTC Type II thermistor for stable readings. Focusensing’s sensors can slot into such systems with better accuracy and environmental resilience.

Industrial, IoT & Consumer Devices

10k NTC thermistors are often used in:

-

Industrial controllers

-

Environmental sensors

-

Smart appliances

-

Medical devices

They are popular because they are affordable and offer good accuracy. Focusensing offers NTC sensors in several series: MF5A-5, MF58, and MFP. These sensors are built for compact, high-precision, and rugged designs.

[focusensing.com]Featured Focusensing 10k NTC Lines

The MF58 series is a chip-in-glass 10k NTC. It has great stability and high precision. This makes it ideal for compact circuits. The MF5A-5 series is a 10k NTC bead. It has an epoxy coating and PTFE-insulated leads. This design makes it great for general-purpose use.

Explore Focusensing NTC Portfolio6. Design & Selection Guidelines

- Select tolerance and Beta stability based on target accuracy.

- Limit excitation current to avoid self-heating.

- Choose packaging (epoxy, glass, hermetic) depending on environment.

- Apply pre-aging or cycling stress to reduce drift.

- Ensure soldering temperature/time constraints are respected.

7. Future Trends & Innovations

New advances in nanocomposite thermistors, flexible sensors, and on-chip drift correction can enhance 10k NTC thermistors. These improvements enhance form factor and stability significantly. Research has looked at adding conductive particles to polymer matrices. This creates flexible NTC devices.

8. FAQ & JSON-LD Schema

Q: Why choose 10k instead of 5k or 100k?

A: 10k strikes a balance between sensitivity, noise immunity, and compatibility with most standard ADC dividers.

Q: How to reduce measurement error from self-heating?

A: Use minimal current, allow thermal equilibrium, and design proper thermal coupling to the ambient.

Q: What causes drift over time?

A: Material aging, thermal cycling stress, packaging stress, and exposure to harsh conditions lead to drift; mitigation includes stable materials, pre-aging, and quality control.

Q: How to convert resistance to temperature accurately?

A: Use the B-parameter model or Steinhart–Hart polynomial for best accuracy across the full range.

Next Steps

Focusensing’s new 10k NTC thermistor series tackles long-standing pain points: tolerance, drift, packaging, and real-world robustness. With these upgrades, designers in EV, HVAC, IoT, and industrial domains gain a more stable temperature sensing foundation.

If you'd like sample units, calibration data, or assistance in integrating into your design, contact Focusensing today and let us support your next thermal measurement project.

+86-551-69109668

+86-551-69109668