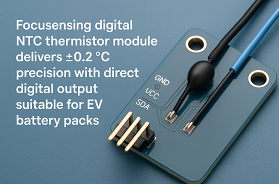

Focusensing introduces a next-gen digital NTC thermistor tailored for electric vehicle (EV) battery systems. It achieves automotive-grade reliability, ±0.2 °C precision, and streamlined digital output—all in a compact, easily integrated package.

Advancing EV Battery Safety with Digital NTC Sensors

The rapid expansion of EVs presents growing thermal management challenges. Battery cells are highly sensitive to temperature variations. Even small deviations can degrade performance, reduce lifespan, or present safety risks. Standard thermistors have served well—but they add wiring complexity and require analog-to-digital conversion (ADC) circuitry.

Focusensing's new digital NTC thermistor changes that. It embeds the temperature sensor alongside digital interface electronics. With a direct microcontroller-compatible output, this sensor streamlines BMS design—reducing board space, power draw, and noise.

Key Specifications

- Precision: ±0.2 °C over –40 °C to +85 °C. Ideal for cell-level temperature control.

- Interface: 1-wire digital or I²C. No external ADC or calibration needed.

- Certification: AEC-Q200 qualified, meeting automotive reliability standards.

- Compact size: Small probe package supports tight BMS layouts.

- Power consumption: Very low standby current, essential for low-power vehicle systems.

How It Simplifies BMS Design

Traditional thermistors require analog signal conditioning, calibration resistors, and ADC pins on the microcontroller. The digital NTC removes all those blocks. BMS systems can now read accurate, calibrated temperature values over a simple digital bus. This reduces PCB layers, BOM cost, assembly complexity, and improves system reliability by minimizing analog vulnerability to electromagnetic interference.

The integrated design also ensures consistent calibration across parts—no human-tuning needed. This is a game-changer for manufacturers deploying high volume EVs.

Meeting Automotive-Grade Standards

Automotive components must withstand severe conditions—extreme temperatures, vibration, moisture, and long-term thermal cycling. Focusensing follows a rigorous quality protocol:

- AEC-Q200 Qualification: Validates thermal cycling, salt spray, and mechanical shock durability.

- ISO 9001:2015 Manufacturing: Focusensing runs production under controlled processes and traceable batch records.

- 2×100% Testing: Every unit undergoes two rounds of testing for accuracy and stability—zero sampling risk.

This triple assurance ensures each digital NTC thermistor maintains performance even across millions of units—the kind of reliability EV OEMs demand.

Automotive Use Cases

- Cell-level sensing: Embedded directly on lithium-ion cells for precise monitoring during charging and discharging.

- Module temperature gradient tracking: Digital probes daisy-chained allow BMS to map temperature across modules.

- Thermal runaway detection: A sensitive temperature rise in one cell triggers safety protocols instantly.

- HVAC thermal loops: Supports smart climate systems by providing accurate temperature input without analog wiring complexity.

Why It Matters for B2B Buyers & Procurement Teams

As EV volumes ramp up in the US and Europe, procurement teams face growing pressure to secure technically advanced and reliable components. The digital NTC thermistor addresses key procurement concerns:

- Reduced BOM complexity: Fewer discrete components on the board.

- Lower assembly cost: One-wire digital communication brings installation efficiency.

- Supplier / VF reliability: Full batch testing ensures zero defects in production runs.

- Compatibility: AEC-Q200 and ISO-certified—ready for automotive-grade supply chains.

Market Context (2025): Growing Demand

By 2030, global EV penetration is projected to reach 25–30%, pushing battery sensor demand to new levels. In Europe, strict Battery Regulations mandate real-time cell-level thermal monitoring. In the U.S., incentives and fast-charging infrastructure likewise raise expectations for cell safety. Accurate thermistor solutions like Focusensing’s are emerging as essential elements in future-proof BMS design.

Learn More & Related Resources

- Explore our full NTC thermistor portfolio

- Request a custom digital sensor solution

The new digital NTC thermistor from Focusensing combines the precision of analog NTC measurement with the simplicity of digital interfaces—designed for the evolving EV battery market. By ensuring high accuracy, full automotive-grade reliability, and seamless integration, this sensor addresses the exact needs of modern BMS design. For EV manufacturers and procurement teams, it represents a strategic advantage in innovation, safety, and production efficiency.

+86-551-69109668

+86-551-69109668